|

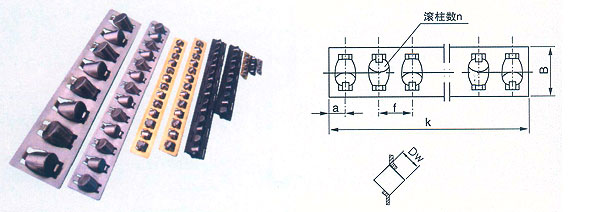

Crossed roller slides are simple, linear motion devices that consist of a stationary base and a moving carriage. They provide low-friction motion and relatively high load-carrying capacities. The rollers are crossed at a 90° angle in an alternating fashion and are enclosed in the rails, which have a machined V-shaped groove to support the rollers. Crossed roller slides resemble ball slides, but provide higher load-carrying capacities and can absorb greater load impacts. Most crossed roller slides have an aluminum carriage and base, steel rods and rollers, and stainless steel end caps. The rollers move between a set of smooth, flat, parallel rods on each side of the base. Although crossed roller slides are not self-cleaning, they are suitable for environments with low levels of dust and other airborne contaminants. Typically, crossed roller slides are more expensive than ball slides.

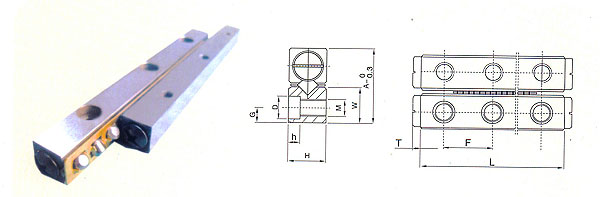

Specifications for crossed roller slides include linear travel, dynamic load-carrying capacity, maximum linear velocity, and physical dimensions. Linear travel is measured in inches (in), feet (ft), millimeters (mm), or centimeters (cm). Dynamic load-carrying capacity is measured in ounces (oz), pounds (lbs), grams (g), or milligrams (mg). Maximum linear velocity is the speed at which the positioning carriage moves. Units of measure include inches per second (in/sec), feed per second (ft/sec), millimeters per second (mm/sec), and centimeters per second (cm/sec). Physical dimensions for crossed roller slides include base length, base width, top height, carriage length, and carriage width. Base length is the length of the base measured parallel to the main axis of travel. Base width is the width of the base measured perpendicular to the main axis of travel. Top height is the height of the unit from the base to the top of the carriage. Carriage length and carriage width are, respectively, the length and width of the carriage measured parallel to the main axis of movement.

Crossed roller slides differ in terms of applications and features. Products that are certified for cleanroom environments are specified according the number of particles per million and the average particle size. Products that are design for vacuum environments are vacuum-rated. Some crossed roller slides include way covers or bellows to protect the rails and guides against the ingress of dust and dirt. Others include wipers or scrapers for cleaning the surfaces of rails and guides. Stackable slides or stages provide linear motion in more than one axis. Locks can be used to slow or stop linear motion, or maintain a specific carriage position. Double-carriage crossed roller slides are also available |

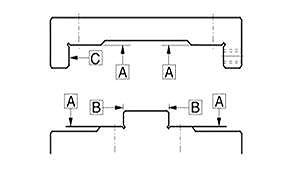

The Precision of matched mounting surface influences the precision and function of movement directly, so it is better to improve the mounting surface’s precision by getting higher precision.

A side: Its precision directly influence the movement precision;

B&C sides: Parallelism directly influence preloading;

Verticality: Verticality opposite to A side influences the rigidity that installed preloading directions

Therefore, we suggest to improve the precision on mounting surface, and the precision valve must border on parallelism value. |

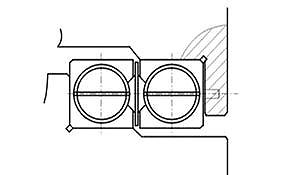

The preloading value varied from machine tools to machine tools and equipments to equipments, Over preloading will decrease the guideway’s lifespan and damage the raceway, at the same time, the cylindrical rollers will be easily deflected and locked by themselves when in the operation, Therefore, we usually recommend to use 0 preloading or less preloading.

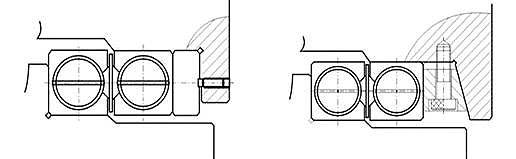

If Higher precision and rigidity are required. The below assembly board as left drawing or the wedge block as the right will be recommended; |