| / We will do attentively.. | Collection / Supposes / E-mail / Site map |

|

| Industry News | |||||||

|

| Basic Technical Parameter |

Rebuilding the Ford Non-Integral Steering Box |

||||

This section pertains mostlt to the Saginaw-designed Non-Integral Reciprocating Ball Steering Box used by Ford from 1960-1980 |

||||

This style of steering box was used extensively by Ford on most of its car lines until phased out by modern rack-and-pinion steering.Often cursed and reviled, it is actually a simple and effective system that was state-of-the-art for many years, being used on everyday drivers and high performance cars alike. Although it could never match the precision of R&P systems, the only real problem with the reciprocation ball system is one of extreme mileage, neglect and misunderstanding. Few people know how to properly rebuild or even adjust a steering box, causing much misinformation to be spread about its supposed weaknesses and problems. But properly assembled and adjusted, a good rebuildable core can be made to operate as well as a new unit again. |

||||

Rebuilding a Ford Non-Integral steering box is seldom an easy thing to do. Before you consider or attempt a rebuild, there are some problem areas you should be aware of. This first part is not designed to scare you off from attempting your own rebuild (well, maybe just a little), but to show you what you may encounter along the way. We have done hundreds of steering box rebuilds and see these problems on a daily basis. These are the things not mentioned in any instruction sheet or shop manual. |

||||

Rebuilding the Steering Box |

||||

Can you rebuild your own steering box? It depends. It depends on the condition of your steering box core, how you remove it from the car, how good of a rebuild kit you are using, and how good the instructions are. Any one of these items can cause you trouble and most boxes have more than one of these problems during a rebuild. The biggest problem is - you don't know what condition your parts are really in until you remove the assembly from the car, tear it down and inspect it. By that time you are into it pretty deep and will have to decide whether to continue on your own or turn it over to a professional. |

||||

By definition, a rebuild means that there are some parts you will retain while reconditioning them to proper working order. There are several important parts inside the steering box that are not a part of a rebuild kit and these are the parts you hope to reuse. Unfortunately, these parts are often damaged due to rust, wear or improper removal/installation, and so have to be repaired or replaced to make for a successful rebuild. We will start with the parts that are universal to all steering boxes and those parts that are most often damaged. |

||||

Problems You May Encounter ( And not really be aware of ) |

||||

WHAT HAPPENS |

||||

In most cases, a steering box needs rebuilding because it has become so loose that it is hard to keep the car going straight down the road without a lot of constant correction. Causes of this looseness is due to excessive play in the bearings or gear wear surfaces or play in the bearing and gear mesh adjustments. This looseness is caused by two main problems; wear and corrosion. Wear is caused by high mileage, poor lubrication and improper adjustment. Corrosion is caused by water getting inside the box and pitting the critical surfaces. |

||||

THE 3 MOST IMPORTANT PARTS |

||||

The three most important parts in the steering box are the Input Shaft/Worm Gear, the Rack Block and the Sector Shaft. It is the condition of these three pieces that determine if a rebuild is possible. Each one has its own vunerable areas that must be examined to determine if the part is re-useable. |

||||

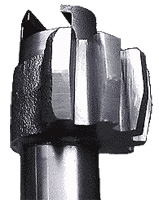

The Input Shaft is turned by the steering wheel. Before 1968 (except in big Fords and trucks) the Input Shaft was a long piece that went all the way up to the steering wheel. Starting in 1968, Ford went to a short Input Shaft design with a coupler connecting the another shaft that went to the steering wheel. This was due to the implementation of the collapsable-style steering column. Regardless of the Input Shaft length, the end that went inside the steering box was made as a Worm Gear. The recirculating balls ride in this twisted gear, moving the Rack Block up and down its length. There are two areas on the Input Shaft that must be examined. |

||||

|

||||

|

||||

|

||||

|

||||

|

||||

It is usually neccesary to shim the upper Input Shaft Bearing to compensate for the metal removed during this process. |

||||

|

||||

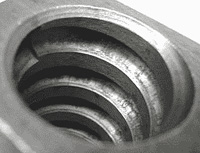

Rack Block:

The Rack Block does double-duty. The inside is grooved to match the Worm Gear. The recirculating balls roll between the Worm Gear and the Rack Block. The outside of the Rack Block also has four teeth on it to mate with the teeth on the Sector Shaft. As the Rack Block moves up and down the Worm Gear, these outer teeth cause the Sector Shaft to twist, which moves the steering linkage and turns the car. The condition of the inside grooves and outside teeth of the Rack Block are critical. |

||||

|

||||

|

||||

One of the most critical points about rebuilding a steering box, and the one most often misunderstood or ignored by rebuilders, is the Gear Mesh Load in the center of steering box travel. Because a steering box spends 99% of its time driving in a straight-ahead condition, the engineers designed in a "tight spot" in the center. This causes the box to have the least possible play while going straight down the road. Without this center tightness, the car would want to wander on the road and would not hold a line well, twitching off whenever the tires encountered something on the road surface. This is the reason most steering boxes are rebuilt - to minimize this looseness. This tight spot is built into the center two teeth of the Rack Block and the space between them. As the teeth on the Sector Shaft move through this section of the Rack Block, the clearances between them gets measurably tighter in the very center. A Rack Block that is damaged or too worn in this center area to provide a tight spot with the Sector Shaft, is too damaged to be re-used and must be replaced. |

||||

Look at the faces of the teeth. The fine lines you see etched into the surface of the teeth are the original factory tooling marks from when the part was machined. These are particularly evident on the faces of the outer teeth since they receive less wear. The more of these tooling marks that are present, the less wear there is on the teeth and the better they are. The most important thing is the wear on the inside faces of the two center teeth. The Rack on the left shows only a slight polishing on its face and most of the tooling marks still evident. You can feel the smoothness of the marking with your fingernail but do not feel and gouging or pitting. The Rack on the right has an obvious shallow area worn into the tooth face that you can easily feel. |

||||

|

||||

The Rack Block on the left is as good as new, despite having many miles on it, and can be re-used. The Rack Block on the right will have too much clearance in the center and will not produce a tight spot when meshed with the Sector Shaft. It cannot be re-used and must be replaced. If the center teeth of the Rack Block are worn enough that you can easily feel a groove or low spot in its surface, it cannot be re-used. A Rack Block with any of the inner tooth surfaces gouged or pitted from corrosion, cannot be re-used. |

||||

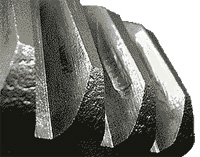

SECTOR SHAFT:

The Sector Shaft has teeth on the top that mesh with the Rack Block. The other end of the Sector exits out the bottom of the steering box and is connected to the steering linkage by the Pitman Arm. On most steering boxes used before 1963, the Sector Shaft was mounted in the case using bronze bushings. About 1963 these bushings were replaced by needle bearings which were used thereafter. |

||||

Just like with the Rack Block, in order for the Sector Shaft to be re-used, the teeth must be in good enough condition to provide a tight spot at the center of travel. On the Sector Shaft, this consists of the condition on both faces of the center tooth. Look for the fine lines that run up and down on the face of the tooth. These are the original factory tooling marks. On the outer teeth you can often see these marks running all the way to the edge of the tooth. Since the center tooth gets the most wear, usually the marks are worn off toward the outer edge of the tooth. If most of the marks are worn off the face of the center tooth, the Sector Shaft will probably not produce a tight spot when meshed with the Rack Block, and so must be replaced. |

||||

|

||||

If any of the teeth faces are gouged, nicked or pitted from corrosion, the Sector Shaft must be replaced. |

||||

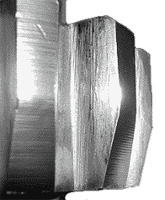

These pictures show a section of a Sector Shaft where one of the needle bearings ride. Water had gotten inside the box and has pitted the surface of the Sector Shaft where the needles are supposed to roll. This kind of damage will cause accelerated wear on new bearings. Polishing the shaft surface will only cause excessive clearance in the fit of the shaft. Any Sector Shaft with this kind of damage should be replaced. |

||||

|

||||

In Summary ... |

||||

As you have seen on the two previous pages, there are several major problems that can be found inside a typical steering box during a rebuild. From our experiance, about 90% of all rebuilds need to have the thrust bearing surfaces of the Input Shaft polished, about 50% will need them machined.. About 20% will need to have the Input Shaft, Rack Block, Sector Shaft or some combination of the three replaced due to excessive wear or metal contamination damage. About 20% will need to have some combination of those parts replaced due to corrosion damage. |

||||

A typical Rebuild Kit from a classic car vendor will contain the Input Shaft Bearings, Sector Shaft Bearings and Sector Shaft Seal. Most will not include a Top Plate gasket or a decent set of instructions. If the Input Shaft/Worm Gear, Rack Block and Sector Shaft are in perfect condition, all the other parts are all re-useable, you have the special tools to assemble and set the measurements, and you have a good instruction set to go by, you can probably rebuild your own steering box. If anything else in your steering box is missing, damaged or needs machine work, you are on your own. |

||||

For knowledgeable and professional rebuilding of Ford Steering Boxes and other power steering parts, go to REBUILDING SERVICES for more information |

||||

If you are in the middle of a rebuild, or are thinking of doing one on your own, we will be glad to help you as best we can. Because we are busy rebuilding during the day, we cannot always help you by phone. But if you send us an email with a description of your problem, we will try and get back to you within 24 hours. |

| Workshop | Products | Contact |

| Copyright © NINGBO CIE INDUSTRY AND TRADE CO.,LTD. All Rights Reserved. Design By HiSupplier Online Inc. |