| / We will do attentively.. | Collection / Supposes / E-mail / Site map |

|

| Industry News | |||||||

|

| Basic Technical Parameter |

| Miniature and instrument-sized ball bearings are high precision machined parts with tolerances and raceway finishes that are measured in millionths of an inch. At the same time, their small size and often thin sections makes them vulnerable to excessive handling forces. High quality bearings cannot be expected to fulfill their performance potential if they are mistreated or contaminated and most small bearing failures can be traced to the user’s poor handling techniques. Common sense in handling a precision part goes a long way towards avoiding such problems, and the user should consider the following as “good manufacturing practices”. | |||

| CONTAMINATION | |||

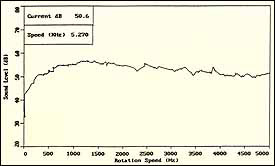

| Bearings are supplied in packages that are usually sealed after final inspection in class 100 clean room conditions. Even sub-micron contaminants can have a serious adverse affect on several aspects of bearing performance: | |||

|

|||

Contamination is avoided by installing bearings in a clean environment. While a clean room or laminar flow

|

|||

| EXCESSIVE FORCE | |||

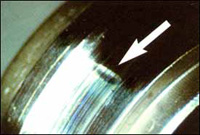

The most common cause of small bearing failure is excessive force applied during assembly, which usually results in the following adverse effects on bearing performance: |

|||

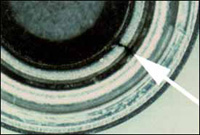

| Brinelling (raceway damage) Noise Higher torque Changed mechanical characteristics Reduced lifetime |

Brinelling causes noise. |

||

|

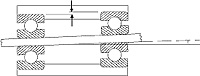

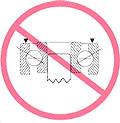

Excessive forces during assembly of small bearings are generated by poor handling techniques or incorrect/uncontrolled interference due to poor design or tolerance stack up. NEVER press fit a bearing to a mating component byapplying force across the bearing raceways through the balls. This will always result in brinelling damage to the bearing. Press the inner ring for a press fit on the shaft or the outer ring for a press fit in the housing. |

||

| Calculate the effect of worst-case tolerances on interference fits. Allow for thermal expansion and material type in calculating the maximum loss of radial play. Use a bearing with suitable radial play range. Loss of radial play will change the mechanical characteristics of the bearing (contact angle, torque, resonant frequency), and can ultimately cause bearing failure. |  Excessive interference has cracked the inner race. |

||

|

|||

| MOISTURE AND HUMIDITY | |||

Bearings are susceptible to corrosion and should be kept in a dry environment. The lubricant in a bearing will provide some measure of corrosion resistance to the internal raceways, but the acid from skin can corrode the outer surfaces. 52100 chrome steel bearings will quickly corrode if the lubricant is cleaned out, so bearings made from this material should never be used “dry”. |

|||

| ALIGNMENT | |||

| Misalignment during assembly is a common cause of bearing noise, increased torque, and general poor performance. The free angle of misalignment that a small bearing can tolerate is typically less than 1°. (See page 13). | |||

|

|||

| MAGNETISM | |||

| Bearings are generally made from magnetic material. If a bearing becomes magnetized, its performance characteristics may change. | |||

| Workshop | Products | Contact |

| Copyright © NINGBO CIE INDUSTRY AND TRADE CO.,LTD. All Rights Reserved. Design By HiSupplier Online Inc. |