The ball screws are the design components of the motion machinery, transmitting the rotatory motion with the high efficiency to the rectilinear motion. They are noted for the high rigidity, accuracy and durability.

Ball screws require the accurate and rigid seating with parallelity of ball screw and guide surfaces up to 0.02mm/1000mm, as well nut unit shall secure its perpendicularity to the longitudinal axis of the screw up to 0.02mm/1000mm.

The nut units can be loaded only in axial direction. The deflection of dead load of the shaft of long and slim ball screws must be eliminated by appropriated way. |

| CONSTRUCTION OF NUT UNITS |

|

Non-preloaded single nut without flange |

|

Non-preloaded single nut with flange |

|

Preloaded double nut without flange |

|

Preloaded double nut with flange |

|

Preloaded single nut with flange |

|

Preloaded high-speed single nut with flange, double leaded |

|

Preloaded high-speed single nut with flange, four leaded |

|

Non-preloaded single nut with flange for rolled ball screw |

|

Preloaded double nut in a sleeve |

|

Servodrive with integrated ball screw |

|

| ACCURACY CLASSES |

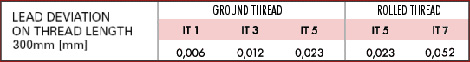

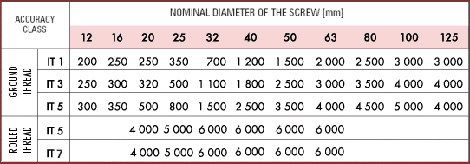

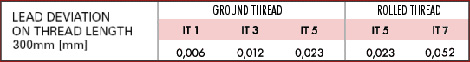

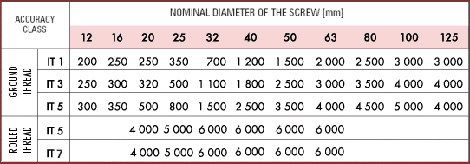

Ball screws are manufactured in 3 classes of accuracy, while lead deviations are in correspondence with ISO standards as it is stated in the next table:

|

| THREAD LENGTHS |

With regard to technological possibilities the limitations are as follows:

|

END OF SCREWS

In principal the end of screws are manufactured according to customer’s drawing.

MATERIAL

The ball screws are made of steel, material 54SiCr6; the nuts are made of material 100Cr6 and 100CrMn6. The above mentioned materials are thermally head treated and this hardness is required in order to ensure the load carrying capacity and the long life of the ball screws. Other materials can also be used to attaine the required qualities for the ball screws, other heat treatment methods can also be employed. The shafts of the ball screws surfaces are medium frequency hardened and the surface hardness of the rolling path of the thread 60 ±2 HRC.

THE LUBRICATION OF BALL SCREWS

The lubrication of ball screws is provided by oil or grease. The way of the lubrication of the ball screws is similar to the lubrication of rolling bearings.

OIL LUBRICATION

In general the same kind of lubrication oils is used for lubrication of rolling bearings. It means mineral oils with minimum viscosity 50 mm2/s at 40 °C. Amount of used oil depends on operation conditions.

In case of the horizontal position of the ball screw, the oil level must reach at least the middle of the lowest set ball in the nut.

Maximum speed of the ball screw:

Internal ball recirculation I: nmax = 100 000 . d0-1

External ball recirculation E: nmax = 70 000 . d0-1

GREASE LUBRICATION

For ball screws are recommended greases acc. grade 2 of DIN 51825:

- KLÜBER Isoflex NBU 15

- OPTIMOL OPTITEMP TT1

It is necessary every 2–3 months to supplement the new grease during running in. The grease must be supplemented after 6–10 months during normal operation. The greases with different conditions must not be mixed together.

Maximum speed of the ball screw:

Internal ball recirculation I: nmax = 80 000 . d0-1

External ball recirculation E: nmax = 50 000 . d0-1 |

| TYPE SERIES OF MANUFACTURED BALL SCREWS |

|