| / We will do attentively.. | Collection / Supposes / E-mail / Site map |

|

| Industry News | |||||||

|

| Current Location: Home >> Products >> Power Transmission Parts >> Ball Leading Screw >> Steel rolled finish ball screw |

| Products |

| Steel rolled finish ball screw |

|

| Order code of ball screw: |

CIE |

- |

D |

- |

16 |

× |

5 |

- |

052 |

- |

RH |

- |

KX |

- |

1111 |

- |

KX |

- |

FM |

- |

VV |

- |

0 |

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

11 |

|

12 |

1.Product name |

2.Specification of screw cap |

3.Metric diameter(Unit:mm) |

CIE=whole group of ball screw including screw cap |

D=according to the standard screw cap of DIN69501 |

|

4.Journey(Unit:mm) |

5.Precision grade of screw |

6.Rotation direction of thread |

|

052=52μm/300mm(Grade P7) Rolling screw |

RH= Right circumrotation |

7.Processing end of screw (one end)(Unit: mm) |

8.Gross length of screw(Unit: mm) |

9.Processing end of screw(another end) |

Kx= without processing |

|

(Unit:mm) |

10.Mode of screw cap |

11.Mode of dust-removing ring |

12.Others |

F=single flange screw cap |

W=with standard dust-removing ring |

0=without |

Sample |

|

1. |

Order whole group of ball screw |

|

CIE-D-25×5-023-RH-K50-1100-K50-FM-VV-0 |

2. |

Order ball screw only |

|

CIS-25×5-052-RH-K50-1100-K50-0 |

3. |

Order screw cap only |

|

CIF-D-25×5-RH-VV-0 |

|

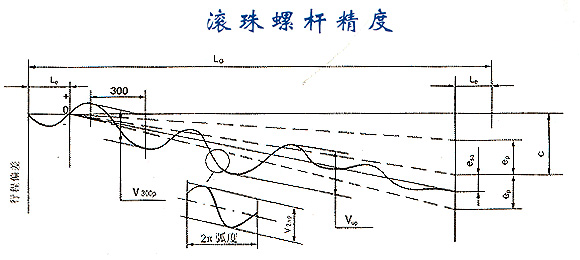

V 300p |

V 2π p |

ep |

ep |

V up |

C |

Variable of inner journey within any 300mm |

Variable of 2π single inner journey |

Average journey error within valid journey ιu |

Average journey error within valid journey ιu |

Variable of journey within valid journey ιu |

The difference between target journey and metric journey within valid journey |

| Safety use of ball screw assembly |

Feature of ball screw Precision of ball screw assembly Selection step of ball screw Safety use of ball screw assembly |

| Lubrication In order to sufficiently display the function of ball screw assembly, it must be lubricated under its working state, and there are two main lubricating methods, as follows: |

| Lubricating grease The volume of lubricating grease is usually 1/3 of inner cubage of nut, GB7324-942# lithium lubricating grease has already injected in the nut when the ball screw leave factory. |

| Lubricating oil Lubricating oil with movement viscidity of 28.5-74cst(400T). The oil volume is confirmed along with using conditions (with restrain volume) as well as others. |

| Dustproof The same as rolling bearing, the ball screw will be abraded soon if feculence or eyewinker enters it. Considering this (scrap), it must use dustproof device (pleat protection cover, ball screw cover, etc.), to completely protect guide screw shaft. In addition, if there is floating dust under the condition that there is not any eyewinker, equip dustproof washer at the two ends of ball bearing nut. |

| Use Following items should be noticed when using ball screw assembly: Ball bearing nut should operate within valid journey, collocate position limit at the two ends of journey if necessary to avoid the nut leaving guide screw shaft to make ball bearing fall off. Because the ball screw assembly has high transmission efficiency but without self-lock ability, when used in vertical transmission, under the condition that the weight of components are not balanced, the reversion caused by deadweight of components must be prevented after the transmission stops or the electricity of motor is cut off. Normal temperature range of working environment of ball screw assembly is ±60℃. Installation |

| Following items should be noticed when installing ball screw assembly: a. The ball screw assembly is only used to receive axial load. Radial and bending moment will make it produce additional surface contact stress or other loads, so as to lead to permanent damage to ball screw assembly. Therefore, when installing ball screw assembly to machine tool, we should notice following items: |

| The axes of screw guide must be parallel with that of the guide rail, which is matched with it, the bearing bush seat on the two ends of machine tool must be on the same line with nut seat; When installing nut, approach the supporting bearing as far as possible; When installing supporting bearing, approach the installation position of nut as far as possible. |

| When installing ball screw to machine tool, do not disassemble nut from guide screw shaft. Use auxiliary cover if it must be disassembled, or the ball bearing may fall off when disassembling and assembling. Following items should be noticed when disassembling and assembling: |

| Outer diameter of auxiliary cover should be 0.1-0.2mm smaller than bottom diameter of guide screw; In the course of using, the auxiliary cover must approach closely to thread shaft collar of guide screw; When disassembling, make sure not to use overlarge strength to avoid damaging nut; |

| Avoid impact and eccentricity when putting in installation hole. |

| NUTS TYPE SPECIFICATION: |

|

|

|

|

|

|

|

|

|

|

|

|

| If there is any design of ball screw nuts or option. Kindly contact us in details. |

| page 1 | page 2 | |

| Ball Leading Screw | |||

|

| Other related category: | Auto Bearings, Industry Bearing, Auto Steering Gears |

| Relative Product : | Ball Leading Screw, Linear Motion Shaft, Linear Guide Rail And Block Assemblies, Precise Crossing Guide Rail |

| Workshop | Products | Contact |

| Copyright © NINGBO CIE INDUSTRY AND TRADE CO.,LTD. All Rights Reserved. Design By HiSupplier Online Inc. |