| / We will do attentively.. | Collection / Supposes / E-mail / Site map |

|

| Industry News | |||||||

|

| Basic Technical Parameter |

Ford Non-Integral style Steering Boxes |

Lubrication |

Ford manual-style steering boxes (those that do not have power steering fluid running through them), use a grease internally as a lubricant - not a fluid. This grease is a moly or lithium-based grease like used in lubricating the suspension and steering linkage. It is thick enough to cling to the internal pieces as they move but soft enough to flow through the box also. The steering box's location near the exhaust manifold and engine also causes the grease to soften and move freely. A liquid lubricant would settle to the bottom of the casing and leak out the bottom seal. |

The inside of the steering box needs to be as fully packed with grease as possible with very little air pockets. As the rack block moves up and down the input shaft, and the sector shaft teeth move across the rack, they should push the grease back and forth inside the box, constantly redistributing the grease and keeping the parts covered at all times. An insufficiently filled steering box will not have enough grease in it to flow around and the parts will only have what grease clings to them for lubrication. Soon this grease will wear off and the parts will be rubbing metal to metal. It is not really possible to overfill a steering box with grease if it is vented somehow. Boxes with long input shafts have no seal where the shaft goes in and excess grease will find its way out there. Short input shaft boxes have fill plugs with venting and excess grease will be forced out there. Grease coming out of the box in these areas is not a sign of problems - it is just venting excess grease and will stop when equalized. |

|

Lubricating the Steering Box |

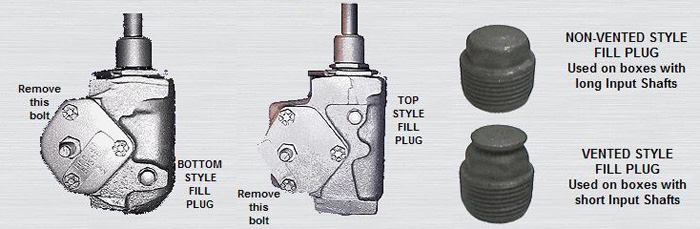

| 1.Locate the Fill Plug on top of the steering box housing. This is usually a stamped, hollow metal plug with a 1/2" hex shape on top. NOTE: As mounted in the car, small boxes such as used in Mustangs, Cougars and early Falcons have the Fill Plug located at the bottom end of the housing. Cars such as Fairlanes, Torinos, Galaxies and Mavericks have the Fill Plug towards the top of the housing. Look at the pictures above and determine which location style your box has. |

| 2.On Bottom Plug style boxes, turn the steering wheel all the way to the right. On Top Plug style boxes, turn the steering wheel all the way to the left. This action moves the rack block inside the housing to the end opposite the fill plug and leaves the area empty. 3.Remove the Fill Plug. Note that there are three hex bolts holding the Top Plate to the housing. Locate the bolt that is the farthest away from the Fill Plug and remove it. On Bottom Fill Plug boxes this is usually a 1/2" bolt, on Top Fill Plug boxes this is usually a 9/16" bolt. 4.Insert the hose end of the grease gun into the Fill Plug hole. Pump grease into the box untill grease starts to squirt out the top plate bolt hole. 5.Reinstall the top plate bolt and the Fill Plug. Turn the steering wheel all the way the other direction. Remove the Fill Plug and top plate bolt and begin pumping grease into the box again. Stop when grease starts to come out the top plate bolt hole. 6.Reinstall top plate bolt and Fill Plug and tighten properly. Turn steering wheel lock-to-lock a few times to distribute grease inside the box. |

| Some grease may appear around the vented-style Fill Plug or where the input shaft goes into the box. This is normal and just the box venting out excess grease. |

The Proper Lubricant |

Ford used a moly-based grease inside the steering box. It lubricates the mechanical actions of the box well, is thick enough to cling to parts without running off and settling to the bottom, and is soft enough to flow back and forth inside the box by the pumping action of the rack block and sector teeth. Heat from the exhaust manifold and engine will soften it on cold days and yet the grease stays thick enough not to liquify and seep out of the bottom seal. A good moly or lithium based chassis grease will work in this situation and is easy to find in tubes and install using a common cartridge-style grease gun. |

Do not use a liquid lubricant (such as 90w axle fluid) in a steering box. Liquid lubricants will settle in the box and not lubricate the upper portions of the gears. It will also seep through the bearings and leak out the bottom seal. Do not use wheel bearing grease inside the box. Wheel bearing grease is too thick to coat and work properly. Wheel bearing grease is designed for the high heat enviroment of the brake system and does not soften with heat and will not flow through the box like a moly-based chassis lubricant will. |

WARNING |

Adding lubricant to a steering box will not help if the box is already damaged or worn inside. A steering box that has excessive play that cannot be adjusted out, rough or ratchety action when turning, or binding will not be cured by lubrication. Installing a heavier grease or a lighter oil will not help. Lubrication is designed to prevent wear and corrosion on parts in good condition and will not compensate for damage or wear caused by prior insufficient lubrication, rust corrosion or improper bearing settings and adjustments. |

| Workshop | Products | Contact |

| Copyright © NINGBO CIE INDUSTRY AND TRADE CO.,LTD. All Rights Reserved. Design By HiSupplier Online Inc. |